We weld quality band saw blades for our band saws and for other band saw manufacturers. Our General Purpose Blade is an excellent blade when cutting a variety of materials.

Band Saw Safety

- Unplug your machine before changing parts or doing any maintenance.

- Wear safety glasses and shields to protect your eyes from airborne material.* Wear a facemask to protect your lungs from dust, especially with the belt grinder.

- Always dress correctly. Never wear loose clothing or ties that might get caught in the machine.

- Never wear gloves when using the drill press.

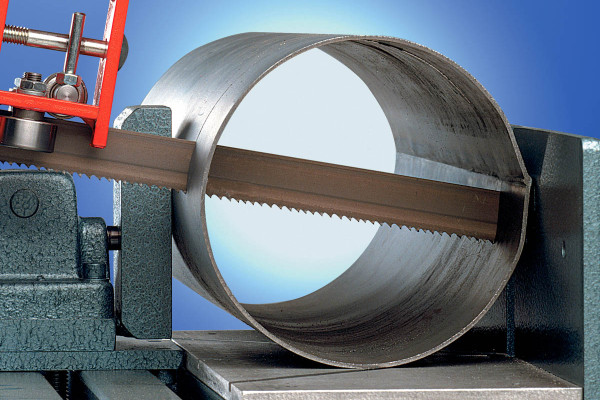

- Use a vise. Never hold the piece being cut with your hands.

- Wear gloves and eye protection when handling the blades.

- Blades are coiled and under tension so it is of utmost importance that you uncoil blades properly.

How To Select The Correct Blade

The first thing to consider when looking for a band saw blade is to answer this question:

What am I cutting?

If you are cutting metal, go directly to Bi-Metal Blades below.

If you are cutting softer materials, look at the Hardback and Flexback blades.

Bi-Metal Blades

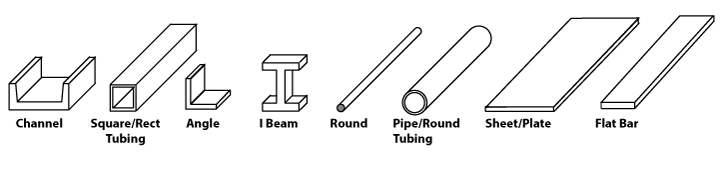

A Bi-Metal blade has a high speed edge material that has been electron beam welded to a fatigue resistant spring backing. If you are cutting in a production setting, you will want to use a bi-metal blade that will cost more but is more economical in the long run as it will outlast carbon blades by up to 5 times. Bi-Metal blades are used to cut carbon steel, tool steel, structural steel, stainless steel, pipes and tubes, die steel, angles and flat stock, and mixed metals.

Determine the size of your blade – Length – Width – Thickness

- Only size and blade material affect the price of the blade.

Select the TPI (Teeth per Inch)

- For long life and the ability to cut a variety of materials, consider the

Ellis General Purpose Blade (GP) - Have at least three (3) teeth in the work surface at all times and not more than twenty-four (24) – optimum is 6 to 10.

- Never run bi-metal blades faster than 500 SFM.

- Break-in new blades properly – see How to Break-in a New Blade

- See Tooth Selection for more help on choosing the TPI

While using your new blade, monitor chip formation:

- Burned heavy chips – reduce feed/speed

- Thin, fine or dusty chips – increase feed

- Curled, shiny and warm chips – optimum feed

Hardback and Flexback Band Saw Blades

Hardback blades are made with carbon steel with a hardened tooth back and tooth. This blade is recommended for cutting materials like wood, plastics, aluminum, brass, and some mild steels.

The Flexback blade is made from carbon steel with a hardened tooth edge and soft back. This blade can be a low-cost alternative for use on wood, plastics, fiberglass, copper, aluminum, brass and bronze. This soft back allows the blade to run at fast speeds, making it popular in the wood industry.

Both of these blades are ideal for use in home woodworking shops.

Breaking-In A New Blade

To break-in your new blade, run it at the recommended speed but at only 1/3rd of normal pressure for ten minutes. Then gradually increase the pressure back to normal using the hydraulic cylinder. Think of this comparison: You can’t write normally with a newly sharpened pencil. You need to carefully wear down the keen lead point before applying normal weight. Breaking-in the blade will increase the life of your new blade and made it work more efficiently, save time by having to install new blades less often and save money by purchasing fewer blades.

Check the wear and adjustment of your guide bearings every time you change blades.

Tooth Selection (TPI)

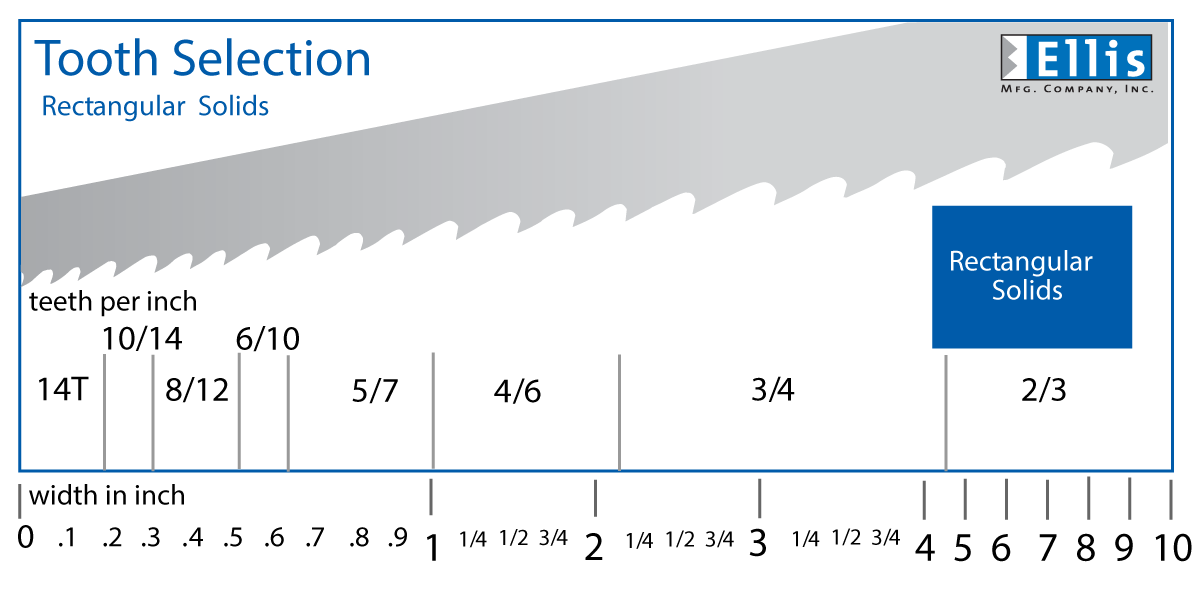

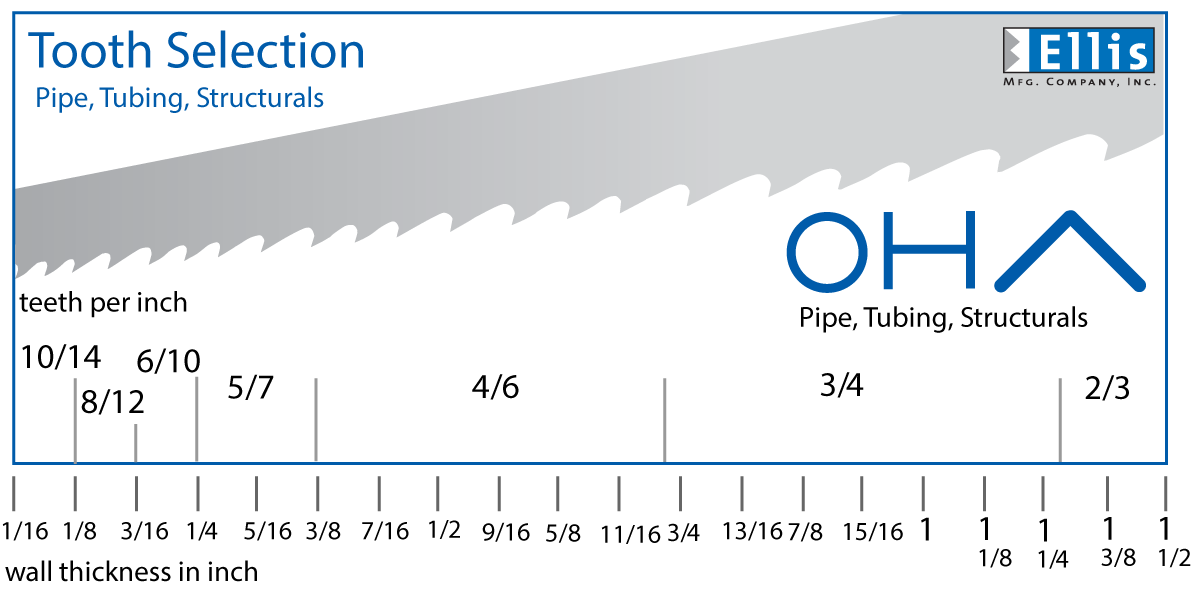

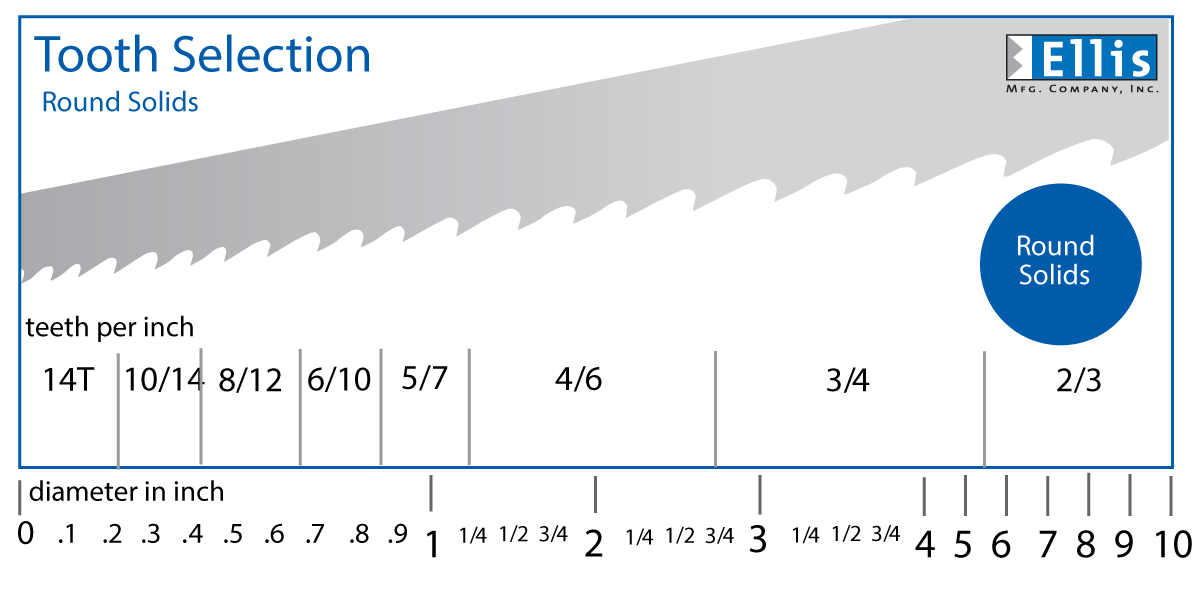

Band saw tooth size is determined by the size and type of material to be cut and the desired finish. Select a tooth per inch (TPI) based on the charts below. Find material dimensions on bottom of chart and move up for appropriate teeth per inch.

To avoid stripping teeth, always have a minimum of three teeth in the work surface.

How to measure TPI: Measure 1 or 2 inches along the blade from the center of the gullet. Count the number of teeth in that space. This is the TPI. A blade’s TPI may not always be a whole number.

In general the following rule applies to choosing the speed of your band saw blade: The harder the material, the slower the speed; conversely, the softer the material, the faster the speed. The faster the speed, the finer the finish produced on the cut surface.

Blade Terms

Blade Length

Simply measure the length of the blade needed. For pricing, go to the next highest half foot. Example- for a blade 5’4 ” go to 5’6″ for pricing.

Blade Width

It is important to use the correct width for your saw as recommended by the manufacturer. With many saws you can use a smaller width but do not go wider.

Blade Thickness

Most blade thicknesses are standard to the width of the blade but some blades of the same width may come in different thicknesses. Try to stay with the same thickness to avoid having to make adjustments when changing blades. Follow the manufacturer’s instructions for adjusting your saw to different thicknesses.

Teeth Per Inch(TPI)

To determine the number of teeth per inch, measure one or two inches of the blade from gullet to gullet and count the number of full teeth between them. This number may not be a whole number on vari-tooth blades.

Blade Materials

There are 3 types of blade materials: Bi-Metal, hardback carbon and flexback. Consider using hardback carbon or Bi-Metal blades for your application for the same reasons that you would decide to use a carbon or high speed drill bit for a job.

Bi-Metal blades are best used for stainless and high carbon steels and other tough materials where higher abrasion and temperature conditions are encountered. Bi-Metal blades can withstand operating cutting temperatures of 1000°F.

Use hardback carbon blades for mild steel and other softer materials.This blade is not recommended for production cutting. Hardback carbon blades can withstand operating cutting temperatures of only 400°F.

Tooth Types & Sets

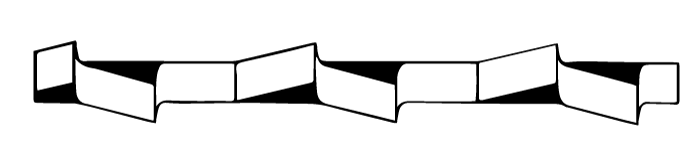

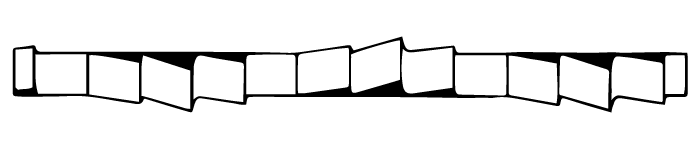

The most common tooth types are the regular tooth and the variable tooth. (Variable tooth is only available in the Bi-Metal).

VARIABLE TOOTH - (Bi-Metal only)

Also known as vari-tooth or broach tooth this tooth has varying set angles and gullet depths. The variable tooth cutting edge reduces vibration while the back absorbs the impacts of cutting in and out of holes, slots and narrow webs. This is the best all-purpose blade for production work and for general shop cut-off and contouring. Use it for cutting off solids bar stock and especially structurals.

REGULAR TOOTH

Straight faced tooth with deep gullets to rake out chips. This style is used for general metal cutting.

HOOK TOOTH

Widely spaced teeth and deep gullets with teeth that have a ten degree undercut face which helps to dig in and take a good cut while the gullets tend to curl the chips. This type is good for harder nonferrous alloys, harder woods and many plastic operations. Available in raker set only.

SKIP TOOTH

Very similar to the hook tooth but characterized by a straight 90 degree, this tooth has a sharp angle at the junction of the tooth and gullet. This type tends to break up the chips. This style is good for soft nonferrous metals that have a tendency to gum and clog the blade and it is also popular in wood cutting. Available in raker set only.

Tooth Sets

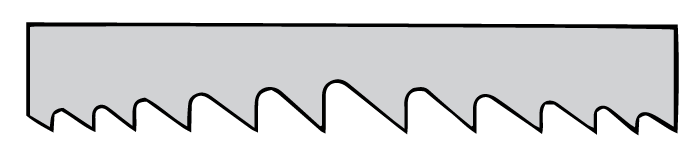

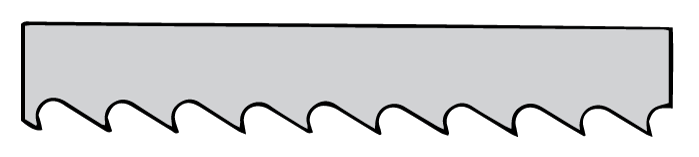

RAKER SET

RAKER SET has one tooth set to the right, one tooth set to the left and one tooth is straight. This is used for most production cutting of thick, solid metal sections on horizontal saws.

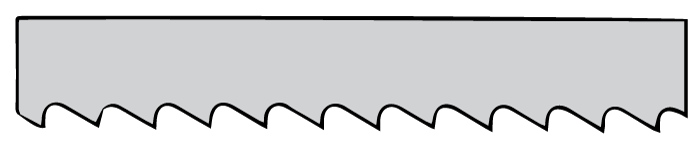

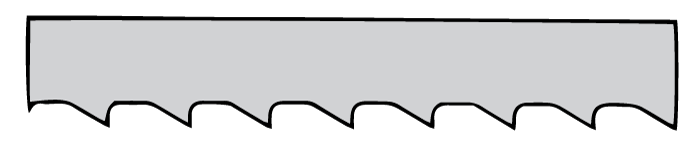

WAVY SET

WAVY SET has teeth set in groups with gradual increasing set to left and right. It is generally made with many teeth per inch and used for cutting thin sections such as sheets, tubes, pipes and small shapes.